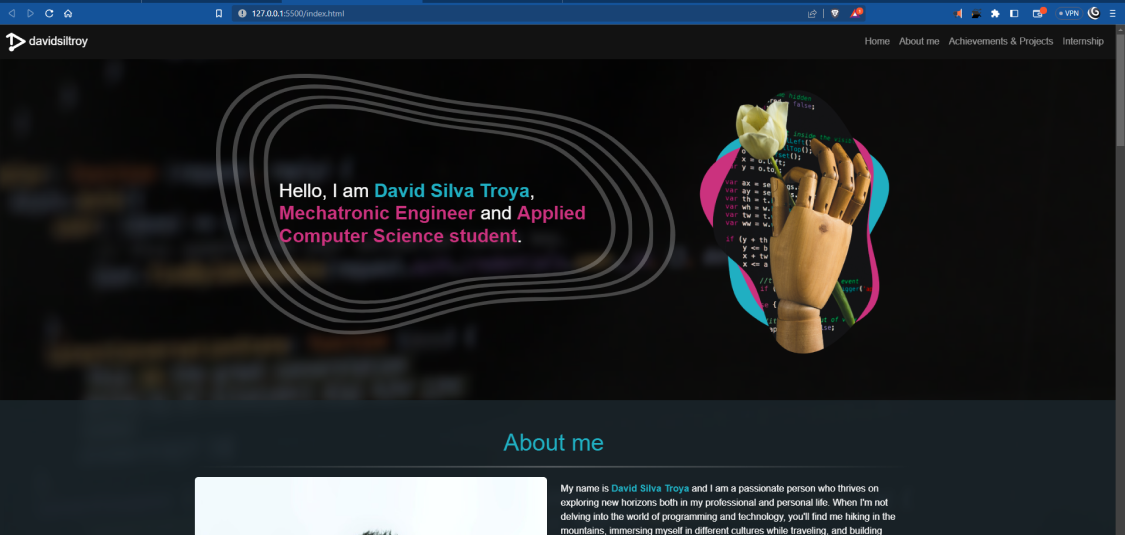

Hello, I am David Silva Troya, Mechatronic Engineer and Applied Computer Science student.

About me

My name is David Silva Troya and I am a passionate person who thrives on exploring new horizons both in my professional and personal life. When I'm not delving into the world of programming and technology, you'll find me hiking in the mountains, immersing myself in different cultures while traveling, and building genuine connections with the locals.

Recently, I've developed a keen interest in archery and have become a member of a local club, even participating in friendly competitions among other clubs. Despite my years of academic study, I have always found time to work during vacations, often assisting technicians in various fields.

What truly excites me is the opportunity to continually learn, connect the dots, and help others see things from a fresh perspective. I believe in the power of understanding and strive to make a positive impact by sharing knowledge and insights with those around me.

Mechatronics

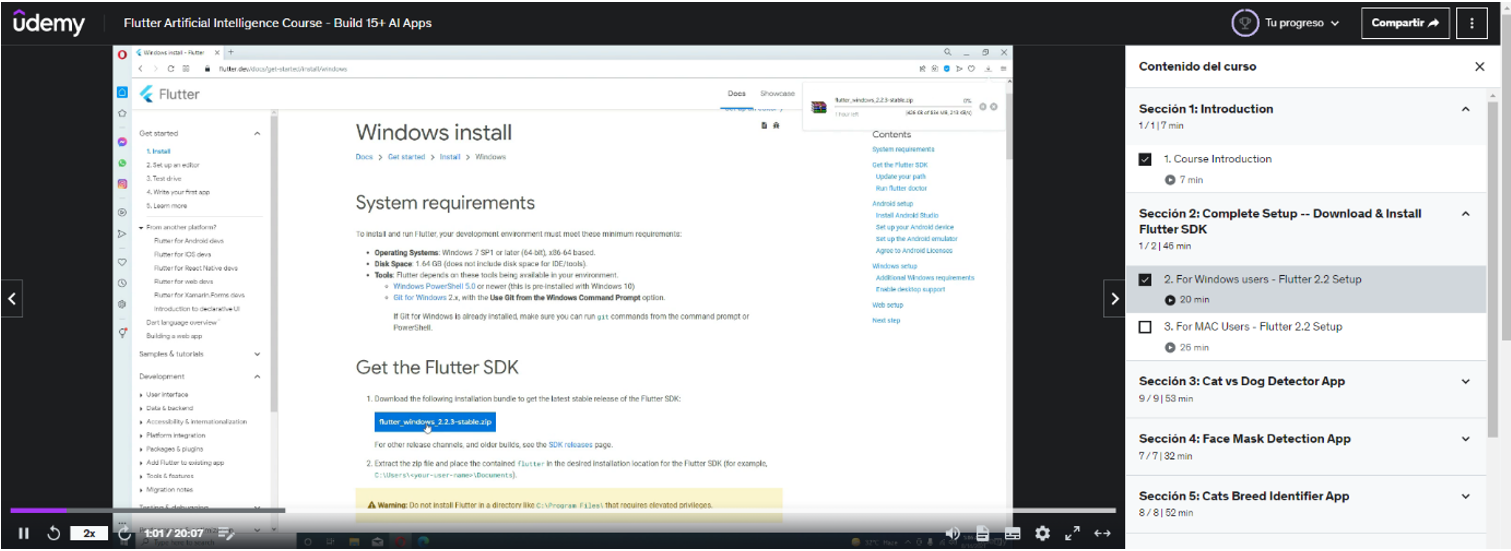

From 2014 to 2021, I was a student at Universidad Técnica del Norte (UTN), which is located north of Ecuador. There I obtained my degree as a Mechatronic Engineer and, with the knowledge gained in automation, I found that I wanted to know more about programming, more specifically Artificial Intelligence.

Applied Computer Science

Since February 2022 I am student at Thomas More - Campus Geel in Belgium. To get my second diploma, in Applied Computer Science in which I have learned about Artificial Intelligence, Big Data, Data Science, Business Intelligence and Data Engineering.

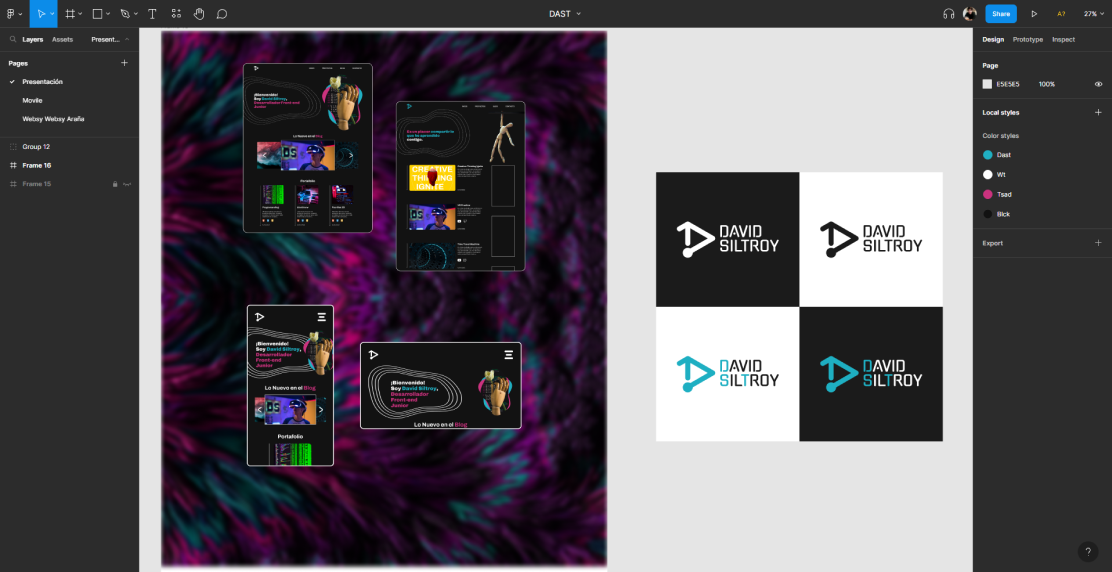

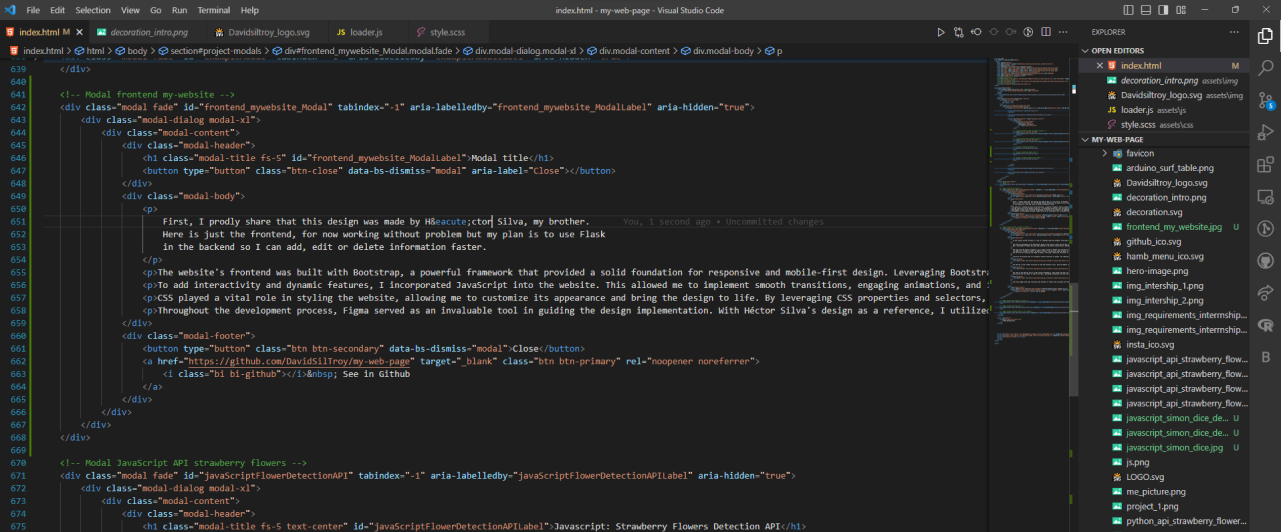

Achievements & Projects

Internship

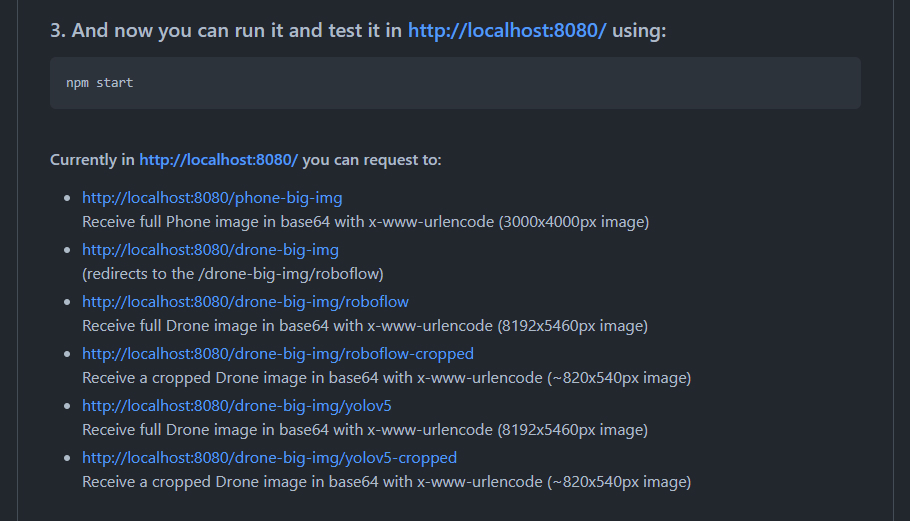

Stock Management System at CERcuits

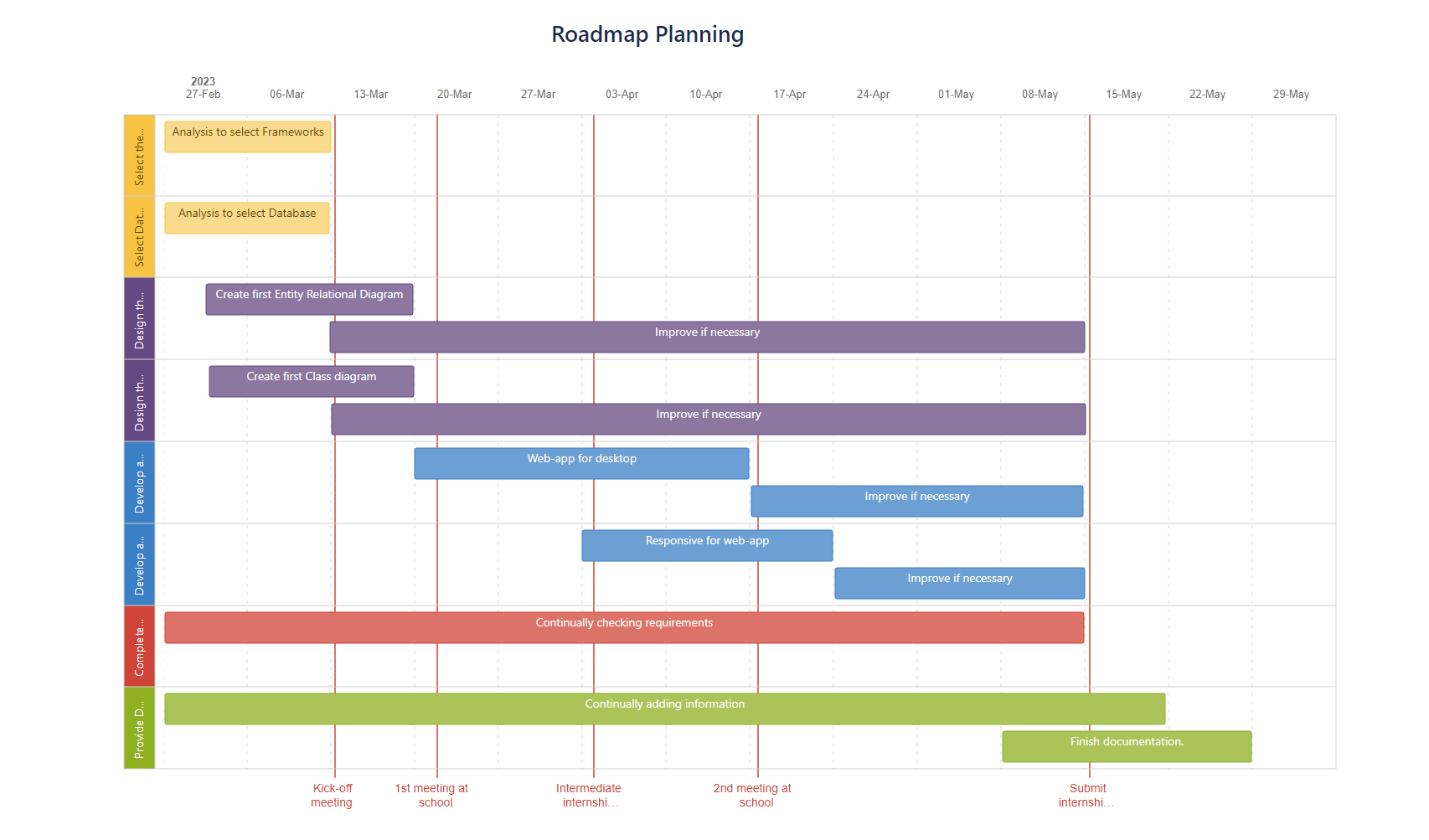

During my 13-week internship at CERcuits, which took place from February 27, 2023, to May 26, 2023, I worked on improving the company's inventory system. CERcuits specializes in ceramic PCB and substrates for prototypes and small series, and as the company grew, there was a need to enhance the existing inventory management process.

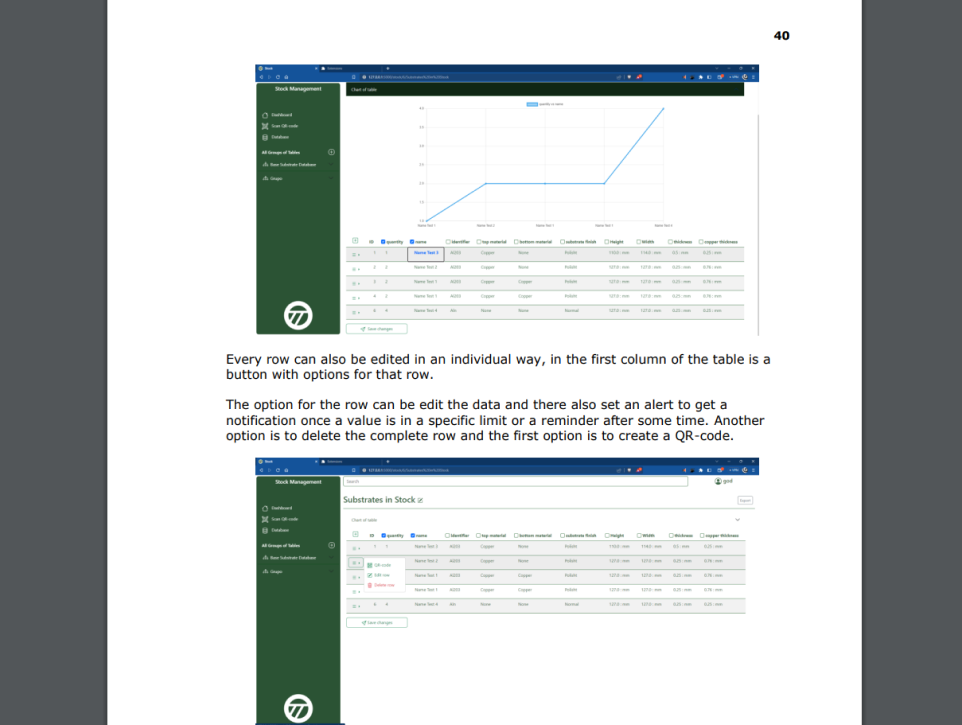

The current manual data storage method was time-consuming and inefficient. Therefore, the main objective of my assignment was to develop a Stock Management System that would offer better control over inventory and send notifications based on specific parameters, such as low stock levels or approaching expiration dates.

As CERcuits expanded its client base, received more orders, and dealt with a wider range of products, managing inventory manually became increasingly challenging. The Stock Management System aimed to address key questions such as product availability, location, order requirements, timelines for reordering, and expiration date information.

To implement the Stock Management System, I conducted a thorough analysis of the company's requirements, considering various options that aligned with the assignment's objectives and weighed their pros and cons.

Documents

Below are the documents I created as part of my internship:

| Evidence: | Evidence for Realization |

| Reflection: | Reflection of the internship |

| Project Plan: | Project Plan at CERcuits |

| Project Plan video: | Project Plan at CERcuits (youtube) |

Requirements

The assignment had specific requirements that needed to be met, although they were subject to change as further research was conducted. The most important requirements included:

- Preference for the use of open-source software.

- The core application should run on a virtual machine.

- Virtual Machine works with a Linux operating system.

- Selection of frameworks and a Relational Database.

- Documentation with UML diagrams, database structure, and user stories.

- Development of a web browser version of the Stock Management System.

- Development of a mobile version of the Stock Management System.

- Documentation of the developed Stock Management System.

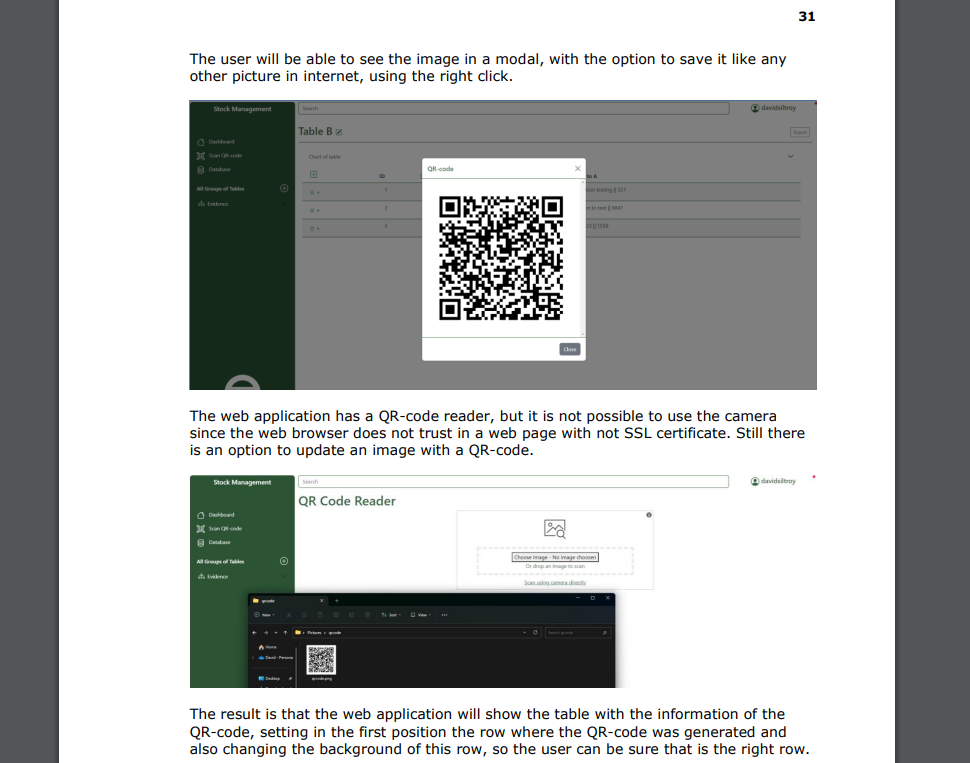

What was expected

To fulfill the requirements of the Stock Management System, the company needs an automated system with user-friendly interfaces that provide accurate inventory information. This includes the option to scan QR codes to access stock information and update quantities. The system should be accessible through web browsers on computers and a dedicated Android application on mobile phones. Additionally, the system should replace the current stocking method and support the production department.